MULTILAYER PIPE PRODUCTION LINE

Progress through experience!

In 1995, Templet Deutschland GmbH, together with an extrusion partner, delivered the first complete system for the production of multilayer composite pipes.

Since then, much has evolved – in technology, expertise, and performance.

Rely on over two decades of experience and discover the advantages of state-of-the-art technologies.

Multilayer forming- and welding line

Templet Deutschland GmbH designs, manufactures and supplies complete forming and welding systems for the production of multilayer composite pipes.

The extrusion machines for the inner and outer layers are sourced exclusively from renowned manufacturers – allowing Templet Deutschland GmbH to focus for many years on the metal sheathing process and to continuously develop innovative solutions.

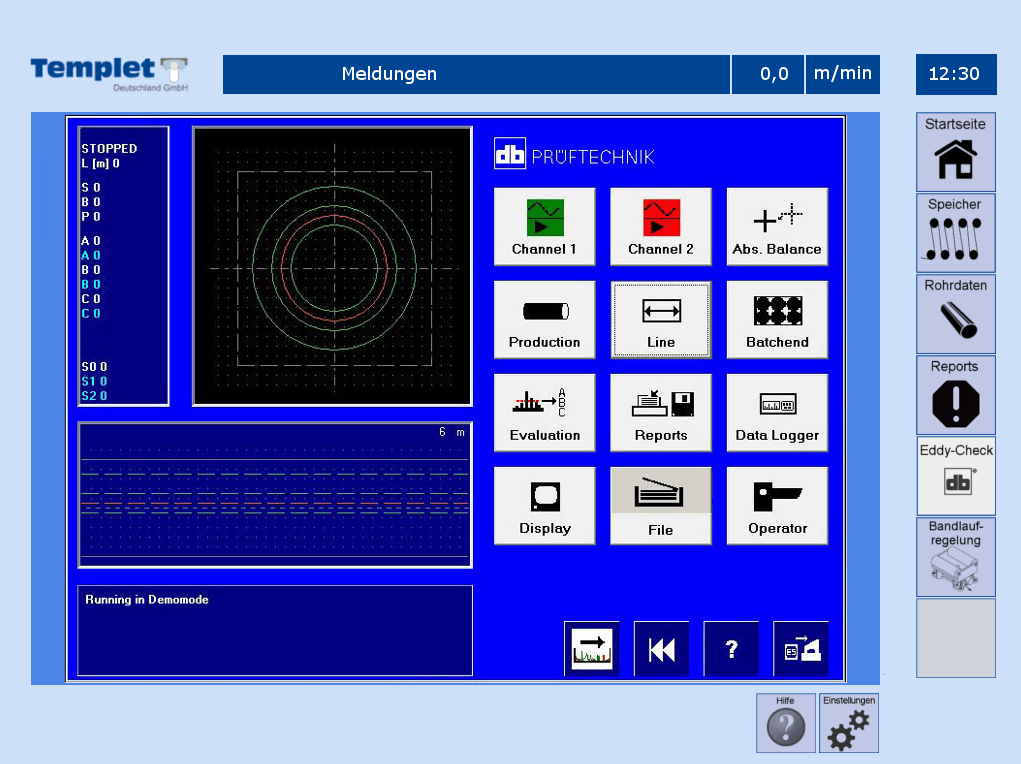

In close cooperation with our long-standing partner in the extrusion sector, we have developed unified control concepts and user interfaces.

The result: a seamlessly integrated production line with a harmonized control system – offering an intuitive “one-look feeling” that ensures fast onboarding and user-friendly operation.

We also set standards in performance:

As early as 2006, we broke the then speed record in multilayer composite pipe production with 50 m/min.

In 2025, we significantly surpassed this achievement by reaching a new record of 80 m/min – another milestone in our ongoing technological evolution.

We are proud to say:

A large number of composite pipe manufacturers rely on Templet production lines for their operations.

MULTILAYER PIPE PRODUCTION LINE

Advantages of our lines:

Advantages of our lines:

MULTILAYER PIPE PRODUCTION LINE

Technical specifications:

Structure of the metal sheathing system:

1. Strip preparation

The strip preparation, also, consists of two Uncoiler, a cross welding machine and a accumulator. The strip preparation thus ensures endless production.

2. Strip trimming

In order to remove all oxide layers and damage to the tape, we trimmed (cut) the tape on both sides by approx. 0.8mm -1.5mm. The desired bandwidth can easily be achieved via the Trimming station

can be set.

The resulting marginal strips are on our Chip winders

wound up.

3. Tube forming

With the help of Roll forming tools

the flat metal strips are formed into the desired tube or profile, also known as forming sections.

In composite pipe systems, the plastic inner pipe is sheathed with a metal band with the help of the molding tool. Low manufacturing tolerances and brilliant surfaces guarantee the highest precision in processing.

In composite pipe systems, the plastic inner pipe is sheathed with a metal band with the help of the molding tool. Low manufacturing tolerances and brilliant surfaces guarantee the highest precision in processing.

4. Welding station

Once the strip material has been precisely shaped into a tube, it must then be welded. Depending on customer requirements, we can equip the system with a TIG welding device or a laser welding device.

5. Pipe calibration

Through the Pipe calibration

the pipe is shaped or calibrated to the desired diameter. This creates a solid bond between the aluminum tube and the plastic inner tube. The end product only receives perfect adhesion values through precise calibration.

Overall system

WELDING PROCESS

Laser - butt welded:

Laser - butt welded:

- Production speeds up to 70m / min

- High quality pipes through fine weld seam

- Ease of use

- No gas is required

- Industry 4.0

- Reproducible values

- Very low scrap thanks to the seam tracking system